- HOME

- Sustainability

- Materiality 3

Sustainable procurement and responsible sales - Sustainability in the supply chain

Sustainability in the supply chain

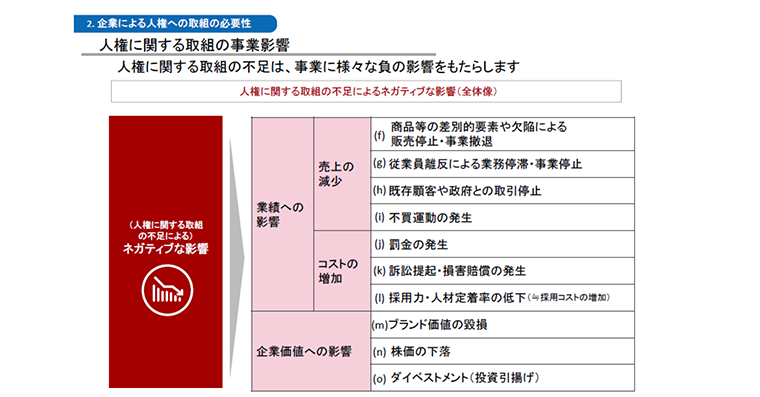

The PPIH group believes that addressing issues related to human rights, labor environment, health and safety for all people involved in its business and reducing the environmental impact of the entire supply chain are important challenges for the group as a retailer. We also believe that fulfilling our social responsibility in the supply chain will contribute to the realization of a sustainable society and lead to the growth of both our suppliers, and the group itself. The supply chain management subcommittee, a subsidiary organization of the sustainability committee, is taking the lead in promoting responsible procurement throughout the supply chain based on strong partnerships with suppliers, in accordance with the "Guidelines on Respecting Human Rights in Responsible Supply Chains" issued by the Ministry of Economy, Trade and Industry (METI) and other international guidelines.

PPIH group supply chain code of conduct

In January 2022, the PPIH group established the PPIH group supply chain code of conduct in an effort to procure products that take human rights and environmental issues into consideration.

In November 2023, reflecting international guidelines, consultations with external organizations, and expert advice, and with the approval of the board of directors, we revised items related to the working environment in the supply chain (payment of a living wage, prohibition and reduction of excessive overtime work, etc.) and environmental protection (introduction of renewable energy, effective use of resources including water, prevention of pollution, etc.).

PPIH group supply chain code of conduct (Excerpt)

- ❶Respect for human rights

- ❷Management of working environment, safety and health

- ❸Fair and transparent business activities

- ❹Environmental protection(Efforts to procure sustainable energy, use resources such as water efficiently, and prevent pollution.)

- ❺Quality control

- ❻Information security

- ❼Contributing to the local community

- ❽Efforts to put into practice

The PPIH group supply chain code of conduct is available in six languages as of June 2024.

| Main target area | |

|---|---|

| Japanese | Japan only |

| English | Overseas common |

| Korean | Korea |

| Simplified Chinese | China |

| Traditional Chinese | Taiwan, Hong Kong |

| Thai | Thailand |

Dissemination of the supply chain code of conduct to suppliers

-Distribution and collection of the supply chain code of conduct and pledge forms

In order to promote respect for human rights and environmental considerations in the supply chain, we ask suppliers who handle PB/OEM products to submit a written pledge that they comply with the "PPIH group sustainable procurement policy" and the "PPIH group supply chain code of conduct". In addition, we ask all new suppliers to submit a written pledge before commencing transactions, regardless of whether they are dealing with PB/OEM products or not.

To date, we have had a total of over 1,800 suppliers submit pledges cumulatively (as of June 2025).

-Briefing sessions

In order to promote responsible procurement that takes human rights and the environment into consideration throughout the supply chain in the development of PB/OEM products together, we have held briefing sessions both in person and online for targeted suppliers in 2022. At these briefing sessions, we explained the objectives and policies of the group's supply chain management efforts, as well as the code of conduct, which includes human rights and environmental content.

Briefing session participation (2022)

- ・No. of suppliers : 740

- ・No. of participating suppliers : 734

- ・Participation rate : 99.2%

Briefing session held in 2022.

Risk assessment and monitoring

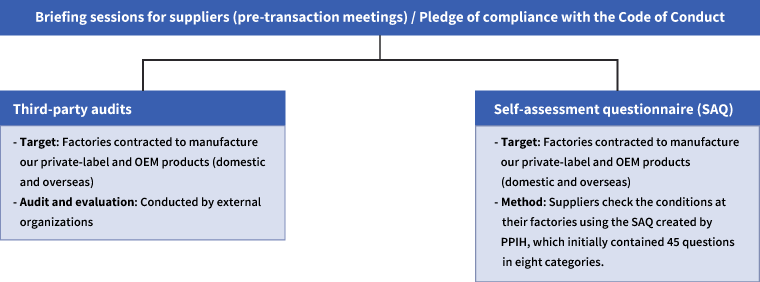

To identify risks in our supply chain and check compliance with the PPIH Group Supply Chain Code of Conduct, we conduct a self-assessment questionnaire (SAQ) and third-party audits for our suppliers. The SAQ is conducted at all factories contracted to manufacture our private-label and OEM products, while third-party audits are conducted targeting factories selected based on various risk management factors such as the scale of transactions, the type of products they manufacture, and the country where the factory is located.

Audits on factories contracted to manufacture PB/OEM products

Self-assessment questionnaire

In June 2022 we created a self-assessment questionnaire (SAQ) for our suppliers based on the ILO Core Labor Standards Handbook and other instruments. Since then we have conducted the survey twice for current suppliers contracted to manufacture our private-label and OEM products. Suppliers check the conditions at their factories using the SAQ and submit their responses. If an issue is identified, we provide the results as feedback to encourage continuous improvement and corrective action. The SAQ initially contained 45 questions in eight categories, and in July 2024 we expanded this to 83 questions in 18 categories for a more in-depth risk assessment. Along with further segmenting questions regarding human rights and labor, we added questions designed to strengthen business continuity and the supply chain.

| Self-check questionnaire survey categories and major items |

|---|

| 1.Human Rights Policy - Whether there is a human rights policy, guidelines, or a system for promoting human rights |

| 2. Child Labor - Whether there are policies, regulations or check functions in place to prohibit child labor |

| 3. Youth Labor - Whether or not there are policies or regulations regarding the employment of young workers |

| 4. Forced Labor - Whether there are policies or regulations regarding workers' rights - Freedom of movement is ensured, and there is no coercion to submit personal identification documents such as passports - There are no penalties or punishments for resignations, and employees may resign of their own free will |

| 5. Inhumane Treatment - Rules prohibiting inhumane treatment, including harassment, and systems for correction and redress |

| 6. Wages and Holidays - Whether or not the company pays salaries that exceed the minimum wage set by the country or region - Rules and management systems regarding employee wages and holidays |

| 7. Discrimination - There is no discrimination on the basis of gender, age, race, religion, sexual orientation, etc. in hiring, compensation, training, promotion, punishment, or dismissal |

| 8. Freedom of Association - Whether or not there are acts that prohibit or hinder the right to organize, freedom of association, and the right to collective bargaining |

| 9. Health and Safety - Proper handling of hazardous chemicals and SDS - Appropriate measures against industrial accidents, etc. |

| 10. Fair Trade and Ethics - Prevention of bribery, illegal donations, and abuse of a superior bargaining position, etc. - Appropriate marketing to consumers |

| 11. Environment - Appropriately manage chemical substances specified by laws and regulations, and ensure that they are not used in excess of the standard values - Aggregation and reduction targets for GHG emissions, water intake and discharge, waste emissions, etc. - Compliance with environmental laws and regulations |

| 12. Quality and Safety - Whether or not the safety standards stipulated by the laws of the country or region in which the product is being sold are being met - Status of quality management system construction and operation |

| 13. Information Security - Cyber security systems and appropriate information management, including personal information |

| 14. Social Contribution - Whether or not the company is engaged in activities that contribute to the development of international and local communities |

| 15. Co-Existence and Co-Prosperity - Responsible procurement of raw materials that pose human rights and environmental risks, such as Palm Oil, Cocoa, and Minerals |

| 16. External Authentication - Status of acquisition of external authentication |

| 17. Supply Chain Management - Whether there are policies, guidelines, and systems in place to promote environmentally and socially conscious procurement |

| 18. BCP - Whether or not a BCP has been formulated and the operational structure |

-Results of self-assessment questionnaire

| Period | Target | No. of factories distributed | No. of factories who replied | Response rate | |

|---|---|---|---|---|---|

| 1st SAQ | June 2022 - June 2024 | Conducted at all factories contracted to manufacture our private-label and OEM products | 2,603 factories | 2,603 factories | 100% |

| 2nd SAQ | July 2024 - December 2024 | Conducted at those factories that were identified as significant from a risk perspective through the 1st SAQ | 159 factories |

159 factories (Domestic 96 factories/ Oversea 63 factories) |

100% |

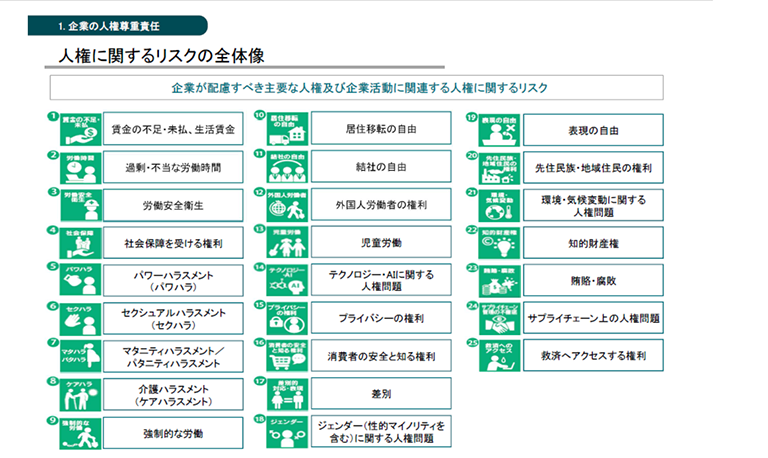

The SAQ responses are evaluated overall based on compliance status with each item and the severity of the risk. We prioritize the areas related to human rights the most, such as child labor, forced labor, prohibition of discrimination, and harassment. After reviewing responses to the past SAQs about serious risks related to human rights, labor and health and safety, we have confirmed that there are no factories where serious risks have been identified, or incidents have occurred (as of December 2024). Through the 2nd SAQ, however, 57 factories were found not to have in place policies or guidelines on preventing child labor, forced labor or discrimination. To encourage improvement at factories, we share SAQ results with suppliers and are also planning training to support them in further respecting and protecting human rights.

-Approach to suppliers to enhance their Initiatives

Follow-up seminars for risk assessment and monitoring are conducted for suppliers who have been identified through the SAQ as having issues that need to be addressed.

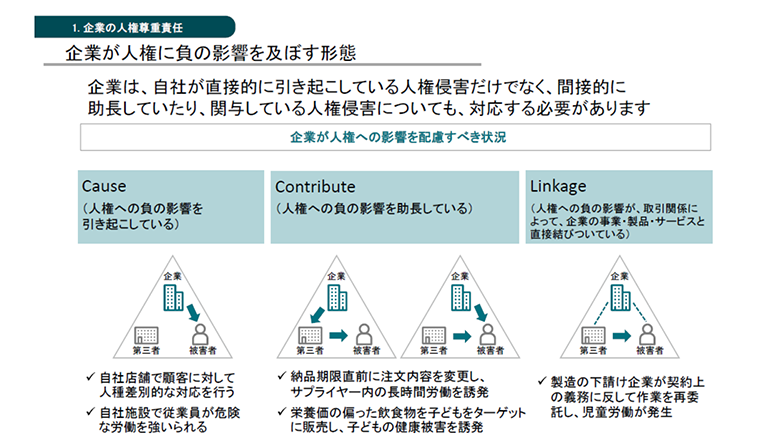

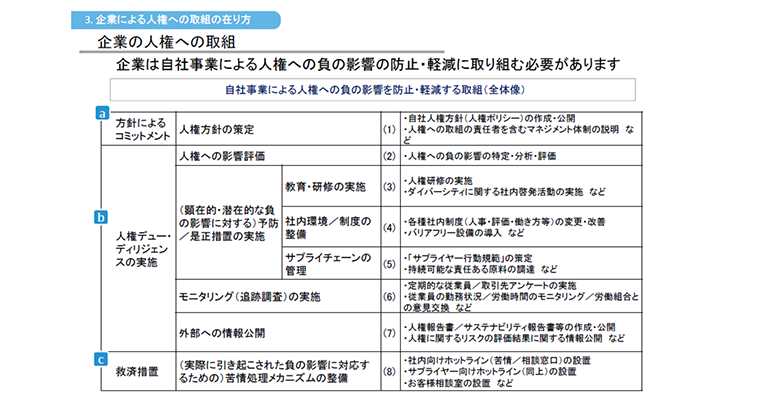

Based on the "Guidelines on Respecting Human Rights in Responsible Supply Chains" issued by METI and other guidelines, we explain the necessary actions companies need to take and provide advice on specific strategies, such as implementing human rights due diligence practices.

・No. of times implemented in 2022 : 12

・No. of times implemented in 2023 : 8

Examples of the materials used in the follow-up seminar

Conducting third-party audits

Among the factories that manufacture our private-label and OEM products, including those under the "Jonetsu Kakaku" brand, the Group has been conducting third-party audits since the fiscal year ending June 2024.These audits target factories that are deemed to be particularly important from a risk management perspective, based on factors such as the scale of transactions, the product genres outsourced for manufacturing, and the countries in which the factories are located.

-Process of Conducting Third-Party Audits

Prior to implementation, we notify the factories contracted to manufacture our products through their suppliers. Auditors then visit the sites to verify compliance with CSR audit items through on-site inspections, document and data reviews, and interviews with managers and workers. To prevent any instructions or retaliation from employers, interviews with workers are conducted privately in a separate room, attended only by the auditors. All materials and images submitted by factories during the audit are appropriately managed and stored in accordance with confidentiality agreements, ensuring that no information is disclosed externally.

| FY2025 | FY2026(Planed) | ||

|---|---|---|---|

| Number of factories audited | Domestic | 22 | 13 |

| Overseas | 17 | 39 | |

| Total | 39 | 52 | |

| A | B | C | D | |

|---|---|---|---|---|

| Domestic | 2 | 16 | 2 | 2 |

| Overseas | 3 | 8 | 6 | 0 |

| Total | 5 | 24 | 8 | 2 |

In the fiscal year ending June 2025, we conducted third-party CSR audits at 39 factories both in Japan and overseas. As a result of reviewing the most critical areas of human rights and labor, which we prioritize the most, we confirmed that there were no factories where serious risks or incidents were identified. However, a number of observations related to occupational safety and health were found at many factories. In addition, at factories that received a "D" rating, issues were identified in areas such as deficiencies in fire protection equipment and labor management. These findings are shared not only with the audited factories but also with their respective suppliers, along with evaluation results. We provide specific advice and hold follow-up seminars to encourage improvements based on the findings. Furthermore, for factories that received "C" or "D" ratings in the third-party audits conducted in the fiscal year ending June 2025, we plan to conduct re-audits in the fiscal year ending June 2026.

<< Steps for improvement efforts >>

- ❶Audit reporting

- ❷Sharing of issues

- ❸Discussing and confirming details of initiatives for improvement

- ❹Interviews to confirm progress

In the future, we plan to expand the scale and conduct third-party audits on more factories contracted for the production of PB/OEM products.

Other initiatives related to supply chain management

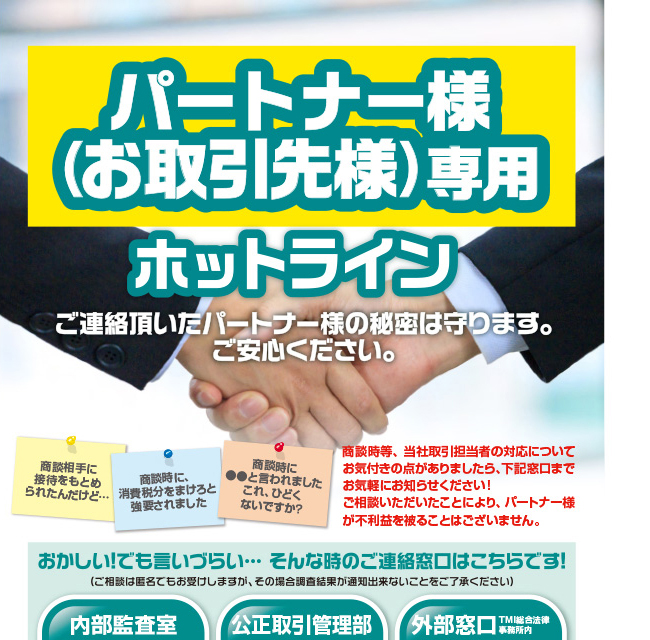

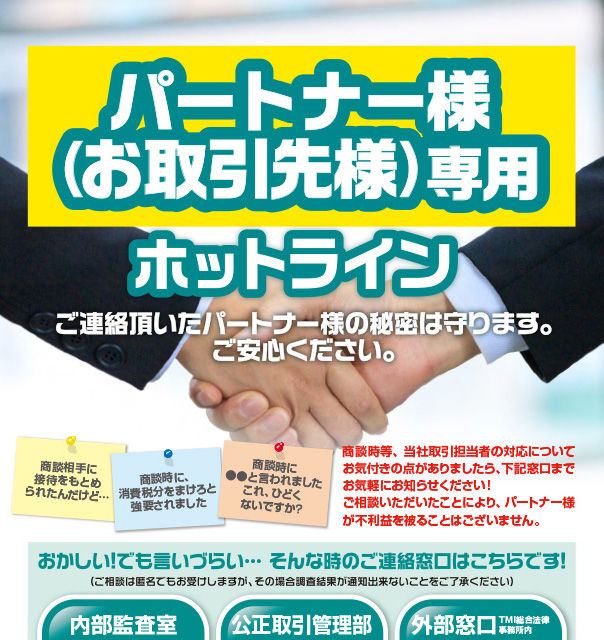

Setting up a hotline for remedial action

The Group has established a reporting hotline exclusively for business partners, including suppliers. Information about the hotline is posted in our business meeting rooms to raise awareness. Both internal and external contact points (third-party law firms) are available, and the privacy of those consulting or reporting is strictly protected. Anonymous consultations and reports are also accepted. It is clearly stipulated that business partners will not be subject to any disadvantage or retaliation as a result of their consultation. We take the feedback received from our business partners through the hotline seriously and work to resolve issues after conducting the necessary investigations.

Number of Reports Received through the Business Partner Hotline (ESG Databook)

Internal education

The supply chain management subcommittee of the sustainability committee plays a central role in the group's training programs for personnel involved in the development of PB/OEM products. The training was based on the "Guiding Principles on Business and Human Rights" issued by UN and the "Guidelines on Respect for Human Rights in Responsible Supply Chains" by METI, and explained the group's procurement policy, human rights and environmental risks in the supply chain, as well as actual cases. 376 participants attended the training held in April 2024.

Examples of the materials used in internal education

In addition, the compliance training we provide to employees every month covers topics related to the Antimonopoly Act and abuse of a superior bargaining position anout once a year, and we are working to ensure that our dealings with business partners do not have a negative impact on human rights.

Endorsement of supply chain initiatives and collaboration with external organizations

-Social field

Declaration of Partnership Building:

In 2024 we made the Declaration of Partnership Building, and we are committed to product procurement with a focus on human rights and the environment, as well as to preventing excessive overtime work at our suppliers.

Our Declaration (Japanese)

Declaration of Partnership Building:

The Declaration is a statement of intent to forge new partnerships through cooperation, coexistence and mutual prosperity with supply chain partners and other businesses dedicated to value creation. It was established in 2020 by the Council for Building Partnerships for the Future, whose members include the Chair of Keidanren (Japan Business Federation), the Chair of the Japan Chamber of Commerce and Industry, the President of the Japanese Trade Union Confederation, and related government ministers.

The Global Alliance for Sustainable Supply Chain

An NGO (non-governmental organization) that works with companies to address issues in the supply chain. At our Group, we began collaborating with this organization in 2025 with the aim of enhancing the effectiveness of our human rights due diligence process, including the identification and remediation of human rights risks within the supply chain.

-Environmental field

Japan Climate Leaders Partnership (JCLP)

We agree with and support the principle that the industry should have a healthy sense of urgency and initiate proactive actions in order to achieve a sustainable decarbonized society, and we are committed to participating in this partnership. Study sessions are also held on the theme of decarbonizing the entire supply chain.